In the world of packaging, speed and accuracy are everything. Products need to move fast. Boxes need to be ready on time. Mistakes cost money, and delays push back shipments. When there’s a lot of cardboard to cut, there’s no room for slow machines or sloppy work. This is where Masterwork stands out as a die cutting machine manufacturer. The brand has become a trusted name for businesses that require extensive die-cutting capabilities daily. And it’s not just because of how fast the machines are, but how well they do the job.

Built to Handle Heavy Loads Without Slowing Down

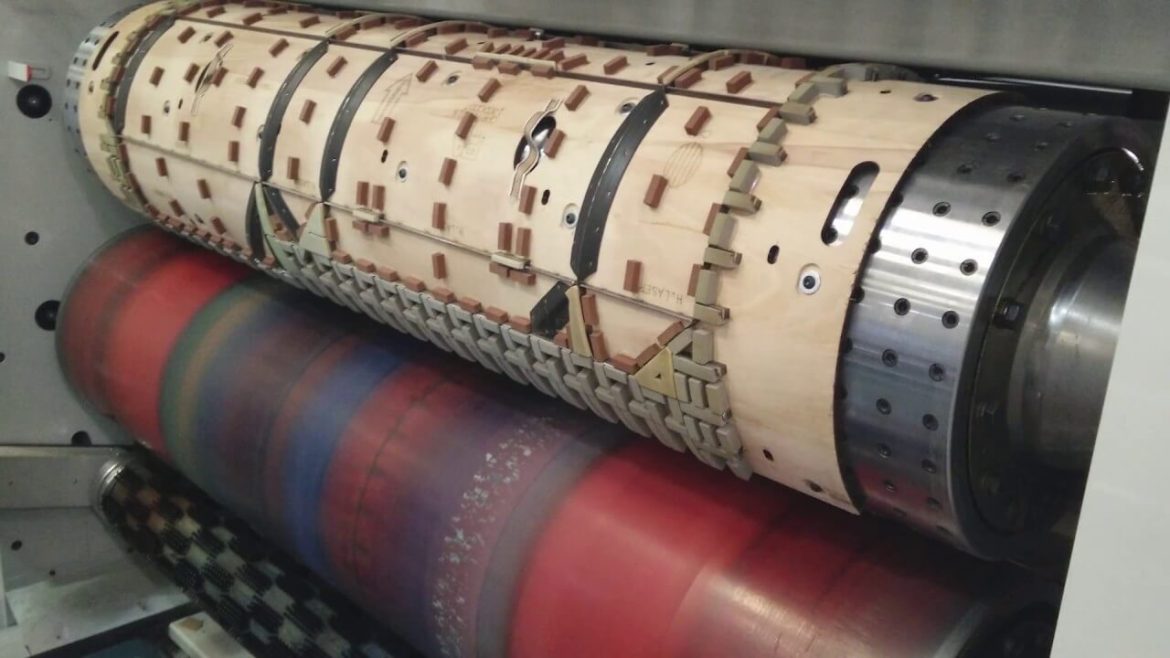

High-volume work can wear machines out. Many cutters start strong but break down after a few months of non-stop work. That’s not the case with Masterwork. Their machines are built to keep going—day after day, job after job. They run smoothly even during long shifts. They handle thick stacks of cardboard like it’s no big deal. There’s less stopping, less fixing, and less worrying. This kind of reliability makes it easier to meet big orders without falling behind.

Clean Cuts That Don’t Miss a Beat

When it comes to packaging, neat cuts matter. A bad cut can ruin a whole batch. Boxes might not fold right. Some may not fit their products. That creates waste—and not just in paper, but also in time and effort. Masterwork die cutters are known for being sharp and exact. They don’t guess—they cut with precision. Each shape lines up just right. Whether the order is simple or has tiny details, the machines stay on target. This kind of accuracy means that less material gets thrown away and more of it is used correctly the first time.

Simple to Run, Easy to Learn

Some machines can be challenging to operate. They have too many buttons and settings. That means longer training and more mistakes. With Masterwork, things are different. The controls make sense. Workers can learn how to use them without needing a thick manual or long classes. That’s a big help when new staff need to get up to speed quickly. Once the machine is running, it’s easy to keep it on track. Settings are clear. Adjustments don’t take forever. And when the next job comes in, switching over doesn’t slow the whole place down.

Keeps Up With Tight Deadlines

In big packaging shops, time is tight. Orders pile up. Customers want their stuff yesterday. There’s no time to wait for a slow cutter to finish up. Masterwork machines are made for that kind of pressure. They don’t just cut fast—they also load fast, align fast, and finish fast. They maintain a steady pace without compromising quality. That means more work gets done in less time. Jobs move forward without backup. Teams stay on schedule. And when unexpected events arise, the machine can handle them without requiring a complete reset.

One Machine, Many Jobs

Cardboard comes in a wide range of shapes and sizes. Some jobs use small sheets. Others need large, thick pieces. Some projects are straightforward, while others have unusual curves and cuts. Masterwork die cutters are ready for all of it. They’re built to work with different paper sizes and thicknesses. They don’t need special tricks to handle tricky shapes. One machine can perform multiple tasks, saving space and money. That flexibility allows shops to take on more orders from more clients without needing a fleet of machines.

Less Waste, More Wins

Waste is a big problem in packaging. A slight mistake can mean piles of bad cuts. And bad cuts cost more than paper—they cost time and money. Masterwork machines are made to reduce waste. They cut clean, even on tough materials. Their tracking systems help keep every sheet lined up just right. And their setup times are short, so there’s less trial and error. With less waste, jobs get done faster, and more materials go to the final product. That’s a win for both the budget and the environment.

A Brand That Stays Strong

Some machines wear down fast. Others need constant repairs. Over time, this adds up. One day of downtime can disrupt an entire week. Masterwork machines are built to last. They hold up under pressure. Their parts stay solid even after thousands of cuts. And when something does need fixing, it’s usually quick and straightforward. That long-lasting design means fewer repairs, more uptime, and better use of every dollar spent on the machine.

Trusted By Big and Small Shops Alike

Packaging companies around the world count on Masterwork. From big factories down to small local retailers, the machines are just as helpful. They accomplish their tasks and also aid in the growth of businesses. With strong performance, simple controls, and dependable cuts, the machines have earned trust across the industry. People know what to expect. And what they get is solid results, time after time.

Conclusion

Masterwork is a top name in high-volume die cutting. The machines don’t just cut cardboard—they help businesses cut waste, save time, and hit their goals. When a shop needs power, precision, and peace of mind, Masterwork delivers—every time.