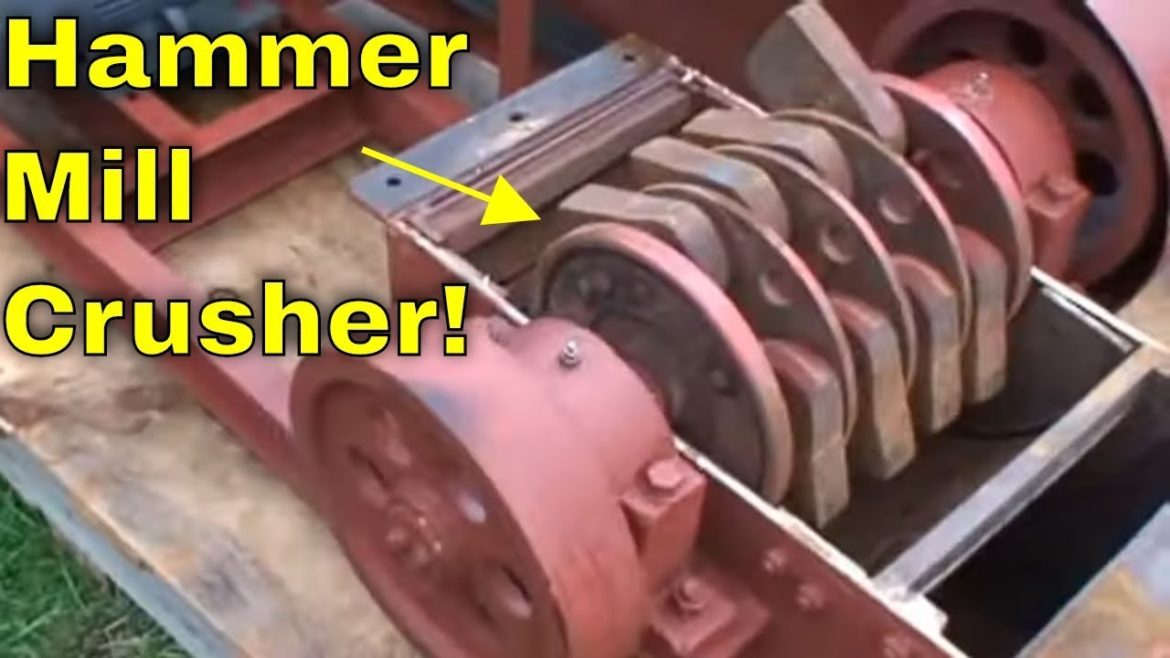

Hammer mill crushers are high-powered equipment that is utilized to grind materials such as wood, rocks, metal scraps and minerals into small fragments. This type of machine operates based on heavy hammers that rotate at high speed and chop down materials through constant collision. As time passes, the hammers get tired from the regular pressure and friction that they undergo while working. When such occurs, then the output of the crusher decreases, the energy consumption is high, and the maintenance expenses increase. To address this issue, most manufacturers have adopted high-grade carbide mulcher teeth in their hammer mill crushers. They are tungsten carbide teeth, improving crusher performance and extending part life. This upgrade increases output and ensures smoother, efficient operation.

Why Output Matters in Hammer Mill Crushers

The productivity of a hammer mill crusher is the amount of material that it is able to work on within a period. High output translates to increased processing and increased productivity. According to industries such as mining, recycling and agriculture, consistency of output is required to ensure that the processes of these industries run smoothly. Wear and tear is, however, one of the biggest problems with hammer mills. The surfaces of the hammers start eroding as they hit hard materials. This causes them to be ineffective in reducing materials to small sizes. Dull or tired hammers may slow down the process and even lead to an unequal particle size. Frequent changes of regular steel hammers necessitate additional time out and additional expense. That is why most manufacturers have resorted to the use of carbide mulcher teeth to enhance the power and performance of the hammer and also decrease wear.

What Makes Carbide Mulcher Teeth Different

The carbide mulcher teeth are made of tungsten carbide, an extremely hard and strong material. It surpasses steel in hardness and resists high heat without deforming. The above attributes ensure that tungsten carbide is quite suitable for hard applications where machines are subject to constant impact and friction. A hammer mill has carbide mulcher teeth that are the main point of contact when crushing materials. They are very hard hence are capable of carrying heavy workloads without becoming fatigued easily. This implies that the crusher remains sharp and useful over extended durations and thus gives the same results despite the harsh working environments. The cutting edges and shape also allow the carbide teeth to give a constant flow of material through the crusher. This eliminates delays, minimizes the chances of congestion and enhances total production.

How High-Grade Carbide Improves Crushing Efficiency

With high-grade carbide mulcher teeth, the hammers can be used to crush hard materials more effectively. The carbide tips also keep their sharp edge, making the crushing action cleaner and more precise. This consumes less energy since the machine does not need to strain to get the same output as much as the machine would have had to do; it can do it more effectively and more uniformly. The increased efficiency also translates to finer and uniform particles produced by the hammer mill. This also matters in such industries as the production of feed, when even the particle size contributes to quality and performance. Another important benefit is heat resistance. Hammer mills may get very hot during continuous running. Normal steel components lose hardness in the presence of high-temperature resulting in quick wear. Tungsten carbide remains stable at high temperatures, allowing the hammer to work efficiently without power loss.

The Role of Material Quality

Carbide teeth are not all formed the same way. Tungsten carbide of high grade is more efficient and durable than the low-quality ones. The purity of the carbide, the bonding process, and the quality of the steel base all influence the duration of the life of the teeth and their performance. The manufacturers of knife blades produce high accuracy and controlled manufacturing to level the end product to meet the high-quality standards of each carbide tooth. This guarantees performance even in the worst situations. A higher grade of the carbide could be a more expensive purchase in the short run, but in the long run, the costs are much less than the end results since the tool could last longer and put up higher production.

Conclusion

Carbide mulcher teeth of a high grade have been a significant factor in enhancing the performance and output of the hammer mill crushers. Their high hardness, heat resistance and longevity will assist them to provide effective crushing action during longer periods, reduce wear, minimize the need to maintain, and provide consistent material flow in machines, thereby providing them with longer life span as well as efficient operation. To industries that use hammer mills in their daily processes, it translates to improved productivity, reduced expenses, and a smoother process. In a short sentence, it is like improving the grade of carbide mulcher teeth to increase the toughness but make it work smarter, last longer, and provide dependable results with each cycle.