Vertical transportation is a vital component of the contemporary world, and elevators are an inseparable part of modern city infrastructure. Elevators provide convenient and easy access in high-rise office buildings and residential complexes. Steel ropes have long powered most elevator systems, but modern technology has introduced an alternative: an Elevator Traction Belt. These cutting-edge belts are redefining the elevator market by providing greater security and improved functionality, as well as being noiseless. Due to the ever-growing vertical growth in the cities, traction belts are set to dominate safe and reliable vertical transport.

What Are Elevator Traction Belts?

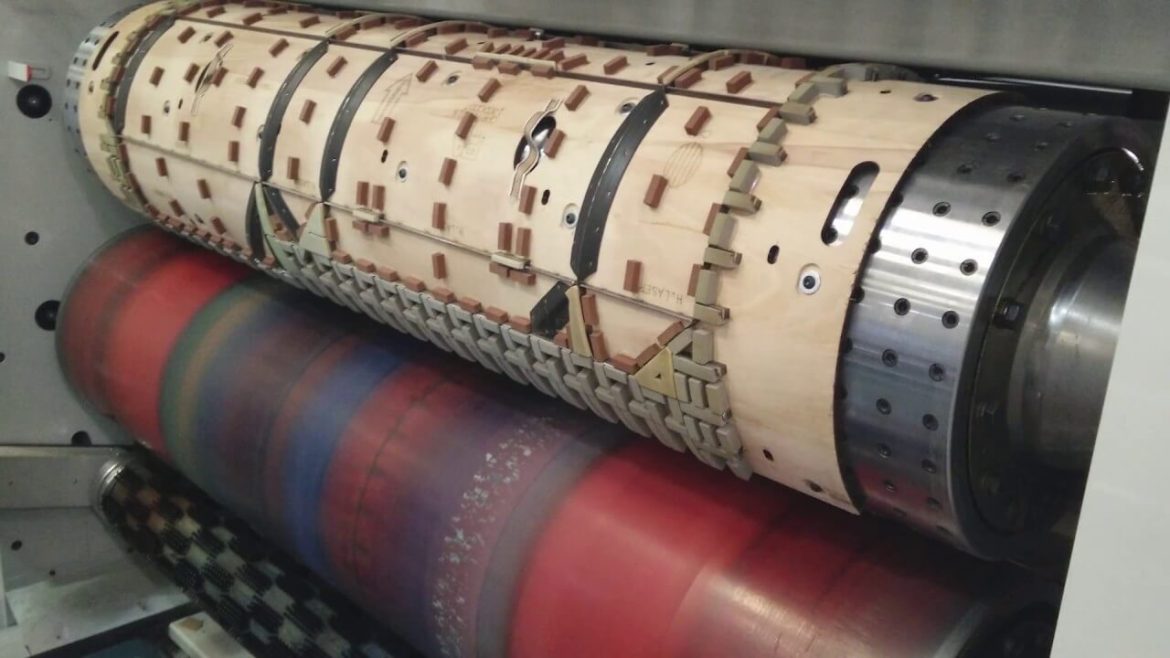

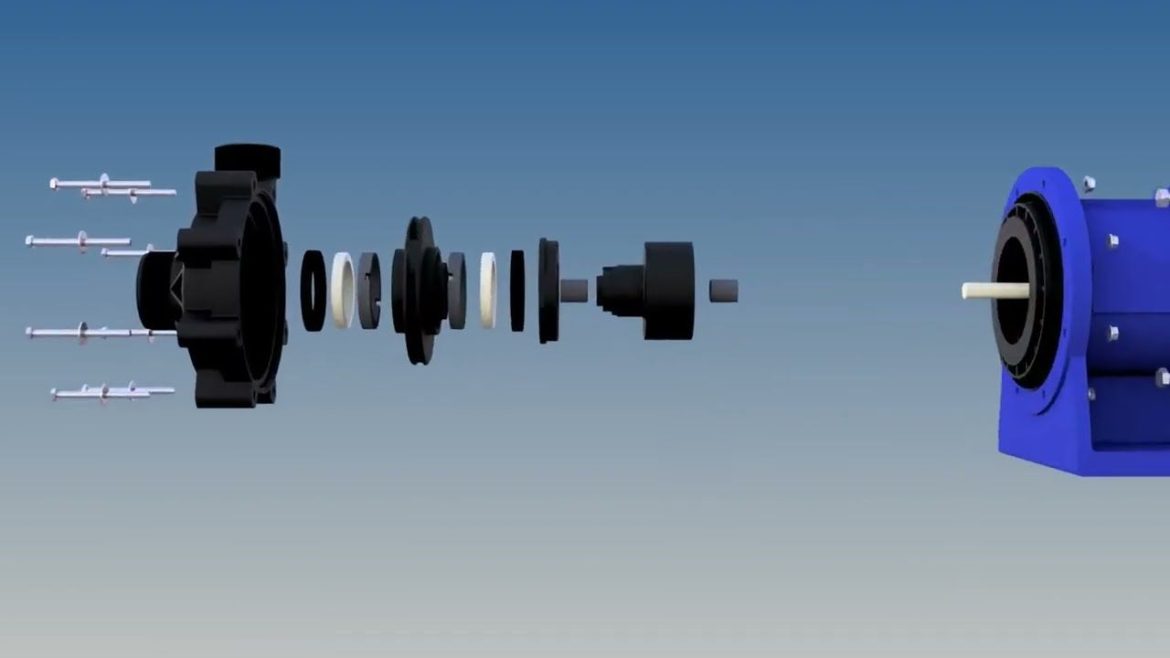

Elevator traction belts consist of high-strength materials in the form of flat, flexible belts that create a connection of power. Traction belts, unlike traditional steel ropes, are made up of several steel or aramid cords in the interior of a polyurethane or rubber coating. This special construction has a good tensile strength, and the weight and the diameter of the belt are considerably minimized. This yields a smaller, more efficient, and durable alternative to the old-fashioned hoisting systems. The belts are currently common in next-generation elevators because they are smooth-running, require less maintenance, and are a better safety measure.

Action of Elevator Traction Belts

The traction belt in an elevator system links the elevator car with the counterweight and has a traction pulley that governs the movement. As the motor rotates the pulley, the friction between the belt and the pulley causes the traction to move the car either up or down. Traction belts have a flat and flexible structure that enables more contact with the surface, which is more efficient in terms of friction as opposed to the usual round steel cables. This improves traction, leading to more precise control, easier acceleration, and reduced noise. Moreover, the lower bending radius of traction belts makes it possible to use smaller pullies, which makes it possible to make machine rooms smaller or even machine-room-less (MRL).

The Benefits of Elevator Traction Belts

The implementation of the traction belts has greatly enhanced the performance of the elevators in a number of major aspects. Safety is one of the most prominent benefits. The aramid or internal steel cords are very strong and resistant to fatigue, which makes breakages unlikely. The solution is also the continuous structure of the belts that removes the strand failures that usually accompany the case of traditional steel ropes.

Quiet operation is another significant advantage. Traction belts do not generate much vibration and noise because they are covered with polyurethane. This makes them suitable for residential structures, hospitals, and hotels, where silence in their operation is vital.

Durability and Maintenance

The striking characteristic of the elevator traction belts is their high level of durability. Traction belts are also extremely tough to environmental factors like humidity and temperature changes, as opposed to steel cables, which may corrode with time. The polyurethane or rubber coating resists wear and oxidation of the internal cords to maintain the consistent performance of the product over the years of constant use.

Maintenance is also reduced significantly as opposed to the traditional systems. The flat design will eliminate dust buildup and minimize frictional wear, which will mean that the lubrication will not be required frequently or that the tension will not have to be adjusted regularly. These visual checks are usually adequate to check on the state of the belt, and this reduces the cost of maintenance and the time wasted.

Increase Design Flexibility

Elevator traction belts allow the architects and engineers more flexibility in their design. Due to their relatively small size and bending ability, they allow building machine-room-less (MRL) elevators, which conserve precious building space. These systems can fit in small shafts and unusual building designs without affecting the performance and safety. Consequently, the traction belts are also contributing to the redesign of elevator design and construction in contemporary structures, which promotes efficiency as well as aesthetic design.

Environmental Impact and Energy Saving

The agendas of sustainability in contemporary construction are growing more important, and elevator traction belts can help to achieve this objective. They are made with a low weight required, which means that the drive motor does not need as much energy, hence lower consumption of electricity. The belts also have a higher replacement cycle, which ultimately reduces the material waste. Traction belt elevators would yield even greater energy savings when integrated with regenerative drive systems and would make them an environmentally friendly solution in eco-friendly building projects.

Conclusion

The elevator traction belt is a significant breakthrough in vertical transportation. Their safety, silence, efficiency, and longevity make them the choice of contemporary elevator systems. The manufacturers are clearing the path towards more compact and energy-efficient designs by substituting heavy and maintenance-intensive steel ropes with lightweight and high-performance belts. With the urban structures increasingly growing, space being the main asset, traction belt technology will be very important in determining the future of vertical movement.